Engineering

COREF Engineering Srl engineers have a complete range of products at their disposal from which they can select the best refractory lining based on customer’s plant characteristics and operating conditions.

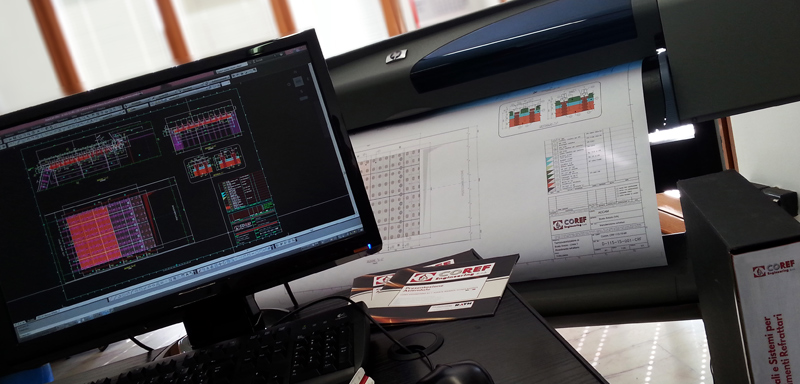

The specific design for each refractory lining is aimed at an engineering, refractory, technical and financial compromise mainly based on experience with similar plants. The technical office provides the necessary support in selecting the quality and the formats of the material to be used, preferring standardized methods, simplifying assembly, maximising plant performance in terms of heat performance and lower maintenance costs.

Based on the specific needs of each maintenance or new implementation, COREF Engineering Srl technically manages works with the determination needed for successfully dealing with ever more demanding tasks.

- Planning and validation

- Estimate drafting, forecast budgets

- Work schedule, work progress report

- Preliminary, standardized and construction drawings

- Standardized technical specifications

- Standardisation of typical linings

- Installation procedures and operating instructions

- Thermal calculations

- QC procedure and technology testing

- On-site inspections

- Refractory selection and procurement

- Planning of ad hoc anchors

- Special precast design

- Special formwork design

- Drawing drafting and Pimus for scaffolding

- Diagrams and instructions for pre-heating and start-up

- Expert reports, measurements and technical reports

- Installation supervision

- Market research and e-procurement

- Archive, Statistics, web platform Management

Engineering Divisions

- Refractory lining engineering in new plants.

- Technical support for revamping/modernisation. Feasibility Study.

- Planned Maintenance Management Expert reports and technical reports.

- Supply and installation of refractory linings with direct site technical and administrative documentation management.

- Project Management.

- Spare Parts Management and Strategic stock storage.

- Refractory lining engineering in new plants.

- Technical support for revamping/modernisation.

- Expert reports and technical reports.

- Supply and installation of refractory linings with direct site technical and administrative documentation management.

- Expert reports and technical reports.

- Supply and installation of refractory linings with direct site technical and administrative documentation management.

- Sale of standard refractory lining products or systems.